9 Questions with Yaning Wei

Dr Yaning Wei graduated from the University of Sydney in 2023 with the Faculty of Engineering PhD Completion Award.

She is now a postdoctoral researcher in the School of Civil Engineering at the University of Sydney, where she is also a member of the Smart Materials and Sustainable Structures (SMS2) group.

1. Within which ACM CRC Research Program/s are you working?

I work within Research Program 1, involved in the Sustainable Waste Management in the Composite Industry project. This project is dedicated to performing an in-depth market analysis of the recycling potential for fibre-reinforced polymer (FRP) composite materials within the Australian context. The initiative seeks to address the pressing issue of sustainable waste management in the composites industry by identifying viable recycling pathways, ultimately contributing to the development of long-term, sustainable FRP recycling solutions. Through this work, we aim to facilitate the industry’s transition towards circular economy practices, minimising environmental impact while optimising resource use.

2. What was the focus of your PhD?

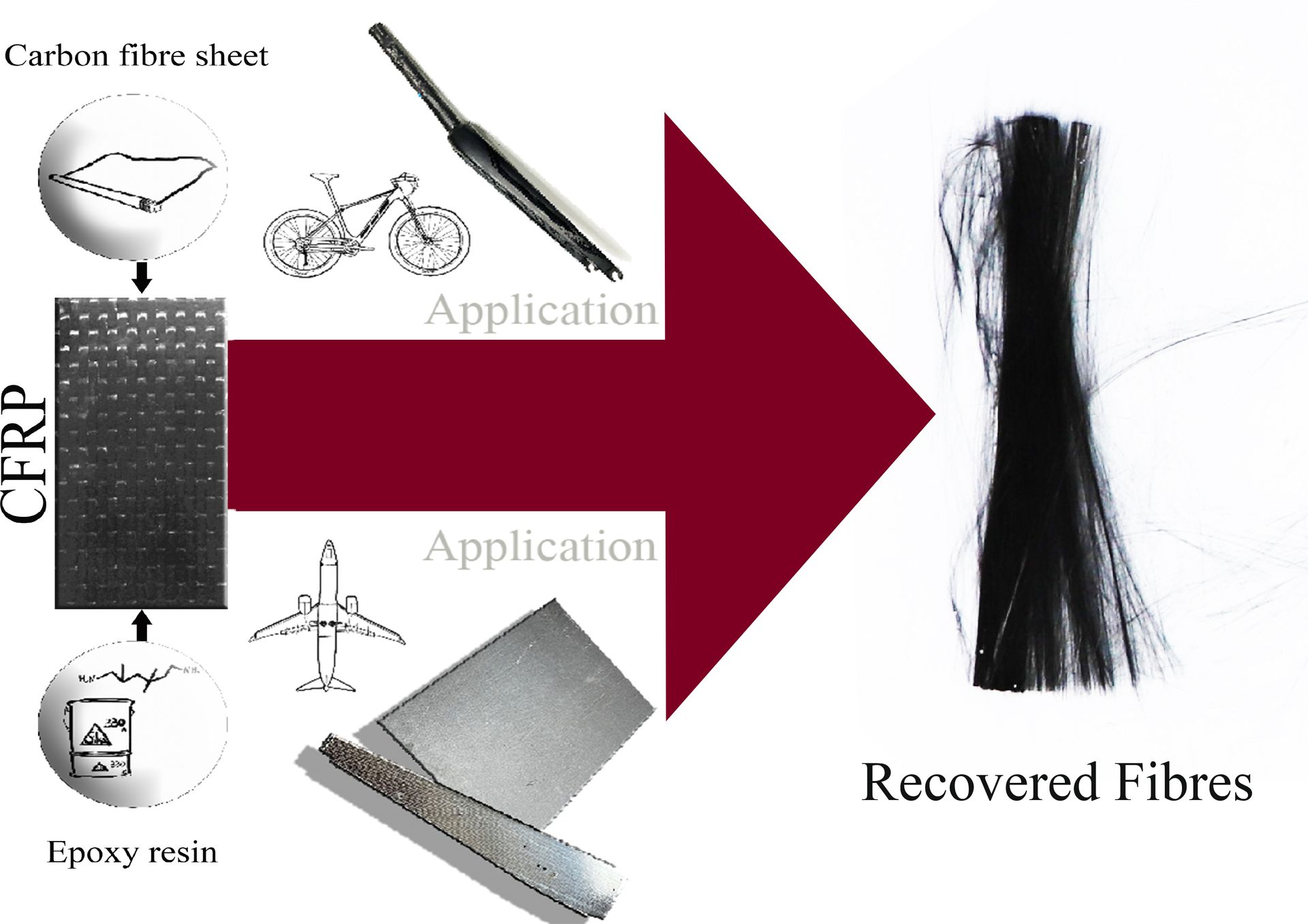

My PhD research was centred on creating a closed-loop life cycle for carbon fibre-reinforced polymer (CFRP) composites. The goal was to develop sustainable strategies for the recycling and reuse of CFRP materials, which are widely used in industries such as aerospace and automotive. This work is crucial for improving material efficiency, conserving energy, and reducing environmental impacts, particularly in light of the increasing use of CFRP in advanced engineering applications. The developed innovative recycling methods maintain the high mechanical properties of recovered fibres while enhancing the sustainability of the composites sector.

3. When did you become interested in this field?

My interest in this field began in 2019, coinciding with the start of my PhD. I became fascinated by the challenges posed by waste management and circular economy principles, particularly in relation to fibre-reinforced composites. As I progressed in my studies, my focus deepened on exploring sustainable solutions for recycling FRP and CFRP materials, driven by the increasing demand for these composites and fibres and the corresponding waste challenges they present.

4. What made you interested in it?

My initial academic focus on green construction and sustainable materials sparked my interest in the lifecycle of advanced construction materials such as FRP. As I investigated the environmental challenges posed by FRP waste, I realised the need for innovative recycling solutions to address the large volumes of material sent to landfills. This led me to explore cost-effective methods for reclaiming the value of fibres from FRP waste, with the objective of reintegrating them into the production cycle, thereby contributing to a more sustainable industry.

5. What can your PhD bring to the CRC? What challenges are you hoping to solve?

This project offers the opportunity to extend my PhD research by conducting a market analysis and proposing future applications. It aims to address FRP waste by conducting a scoping study, encompassing market analysis, waste production mapping, recycling pathways assessment, cost-benefit analysis, and life cycle analysis. The goal is to identify sustainable recycling approaches that Australian industries can adopt to mitigate the growing FRP waste issue. This project will benefit composite manufacturers, environmental agencies, and end-users by providing valuable insights into recycling processes, circular design, waste reduction, and fostering environmentally responsible practices.

6. What are your long-term goals/ambitions?

My long-term goal is to refine the advance combined recycling and fibre realignment technologies that enable the direct production of aligned short recycled fibres. This development would simplify the use of recycled carbon fibre (rCF) in manufacturing and significantly enhance its market acceptance. By creating streamlined processes for incorporating recycled fibres into production, I hope to facilitate the broader use of recycled composites in high-performance applications, contributing to the long-term sustainability of the industry.

7. What’s the best thing about being an ACM CRC Postdoc Researcher?

It is an honour to be an ACM CRC Postdoctoral Researcher. The role provides access to a network of leading researchers and industry professionals, fostering collaboration across disciplines. This collaborative environment not only supports innovative research but also enhances the potential for more practical application. Engaging with industry stakeholders and academic peers alike creates valuable opportunities for the development of new ideas and technologies.

8. What one piece of advice would you give to people thinking of undertaking a PhD in the composites manufacturing area?

For researchers entering the field of composites manufacturing, I would emphasise the importance of considering the entire lifecycle of composite materials, particularly in relation to waste minimisation and recycling. Beyond focusing on optimising recycling processes and integrating recycled materials into new applications, researchers also may explore methods for reducing waste generation during the manufacturing phase, as prevention is the most effective way to manage waste. Embracing sustainability from the outset will ensure that research contributes to the long-term viability of the composites industry.

9. Tell us something about you that would surprise/impress people?

One outcome of my PhD study was the development of an innovative hybrid recycling method capable of recovering high-quality carbon fibres from composite waste, including discarded carbon fibre bike forks and aerospace wasted materials. This method retains high mechanical properties of the fibres, making them suitable for reuse in high-performance applications. We are currently developing more recycling technologies to enhance its scalability and improve its environmental impact.

Interested to know more?

Visit our Education and Training page to learn more on our HDR Program, and how it’s helping to achieve industry transformation.