9 Questions with Mustafa Siddiqui

Our PhDs are playing a significant role within our program, and in the broader industry.

Here, we introduce you to Mustafa Siddiqui, from one of ACM CRC’s university partners, UNSW Sydney.

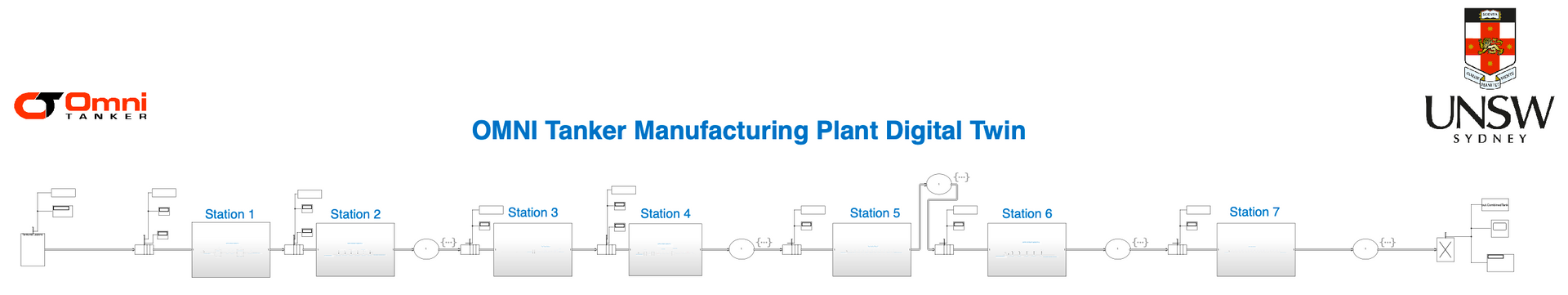

Mustafa Siddiqui is a PhD student at UNSW, specialising in the development of advanced Digital Twin models for optimising manufacturing processes, particularly for Omni Tankers Manufacturing Plant. His research integrates AI and Machine Learning with Digital Twin technology to enhance manufacturing efficiency by detecting and mitigating manufacturing bottlenecks, which are significant obstacles that slow down production. His research also focuses on ensuring efficient resource allocation, production scheduling, and strategic decision-making in manufacturing operations. With a background in publishing research on AI-enabled digital twins and machine learning applications, Mustafa is committed to advancing industrial technology and enhancing operational efficiency in global manufacturing.

1. Under which ACM CRC Research Program does your PhD project sit?

My PhD is part of Research Program 2 and Research Program 3.

2. What is the focus of your PhD?

My PhD research is centred on developing an advanced Digital Twin model aimed at enhancing manufacturing operations. Manufacturing processes are crucial for industries and addressing bottlenecks – significant obstacles that slow down production – is a key challenge. Integrating AI and machine learning with real-time data analytics, my research focuses on detecting current and predicting future bottlenecks.

Furthermore, the research employs prescriptive analytics to recommend proactive strategies for detected or predicted bottleneck mitigation. The digital twin also enables comprehensive scenario analysis for optimal resource allocation for efficient production scheduling, ultimately enhancing key performance indicators (KPIs) in manufacturing.

3. When did you become interested in this field?

I became interested in this field during my Master’s degree, which was entirely research-based. During my degree, I learned the concept of Digital Twin.

4. What made you interested in it?

I developed an interest in Digital Twin due to its divergence from traditional simulation-based approaches. Researchers in academia are actively exploring its vast potential and capabilities. Digital Twin offers innovative solutions to complex challenges in manufacturing operations and can play a significant role in Industry 5.0.

5. What do you hope to achieve through your PhD? What challenges are you hoping to solve?

Through my PhD, I aim to propose a framework for the manufacturing industry to effectively tackle the substantial challenge of manufacturing bottlenecks using Digital Twin. My objective is to propose a methodology that integrates Digital Twin, advanced optimisation techniques, and industrial AI for precise prescriptive analysis to mitigate the bottlenecks to enhance the efficiency of the manufacturing process.

6. What are your long-term goals/ambitions?

My long-term goal is to become a leader in the field of the advanced manufacturing industry. I aim to drive innovation by developing robust methodologies that address manufacturing challenges, ultimately contributing to the advancement of sustainable and efficient production processes.

7. What’s the best thing about being an ACM CRC PhD student?

The best thing about being an ACM CRC PhD student is the opportunity to collaborate with leading composites industry partners in Australia. Engaging in industrial projects provides me with the satisfaction of tackling real-world challenges rather than purely theoretical issues. This practical experience enhances my research and allows me to make significant contributions to industrial advancements.

8. What one piece of advice would you give to people thinking of undertaking a PhD in the composites manufacturing area?

One piece of advice I would give is to actively seek industry connections. Engaging with industry provides invaluable real-world exposure and practical experience that can benefit your research journey. It not only enhances the relevance of your work but also opens doors to collaborative opportunities and career advancements in the field.

9. Tell us something about you that would surprise/impress people?

During my Master’s degree (18-month program), I published two papers within my first year. My research focused on Artificial Intelligence-enabled Digital Twin for predictive maintenance in industrial automation systems, as well as developing a framework for Digital Twin modelling of black box systems using Machine Learning. These achievements underscore my dedication to advancing knowledge in industrial technology through rigorous research.

Interested to know more?

Visit our Education and Training page to learn more on our HDR Program, and how it’s helping to achieve industry transformation.