9 Questions with Joshua Grosser, ACM CRC PhD Student

Our PhDs are playing a significant role within our program, and in the broader industry.

Here, we introduce you to Josh Grosser from one of ACM CRC’s university partners, UNSW Sydney.

Josh is an MPhil student at UNSW, and a Mechanical Engineer with experience in the maritime and composites industry. He’s currently working with ACM CRC Industry partner, Ocius Technology, designing and building the Bluebottle USVs (unmanned surface vessels). Josh is completing an industry research Masters focussed on developing the Bluebottle’s wave propulsion flipper. Teamed with Fangbao Tian and Garth Pearce, they are using data feedback from Ocius trials as inputs into Fangbao’s FSI solver to iterate and improve the vessel’s performance.

1. Under which ACM CRC Research Program does your PhD project sit?

Research Program 2: Manufacturing Processes, Research Program 3: Simulation, Performance Prediction, Research Program 4: Design Integration.

2. What is the focus of your PhD?

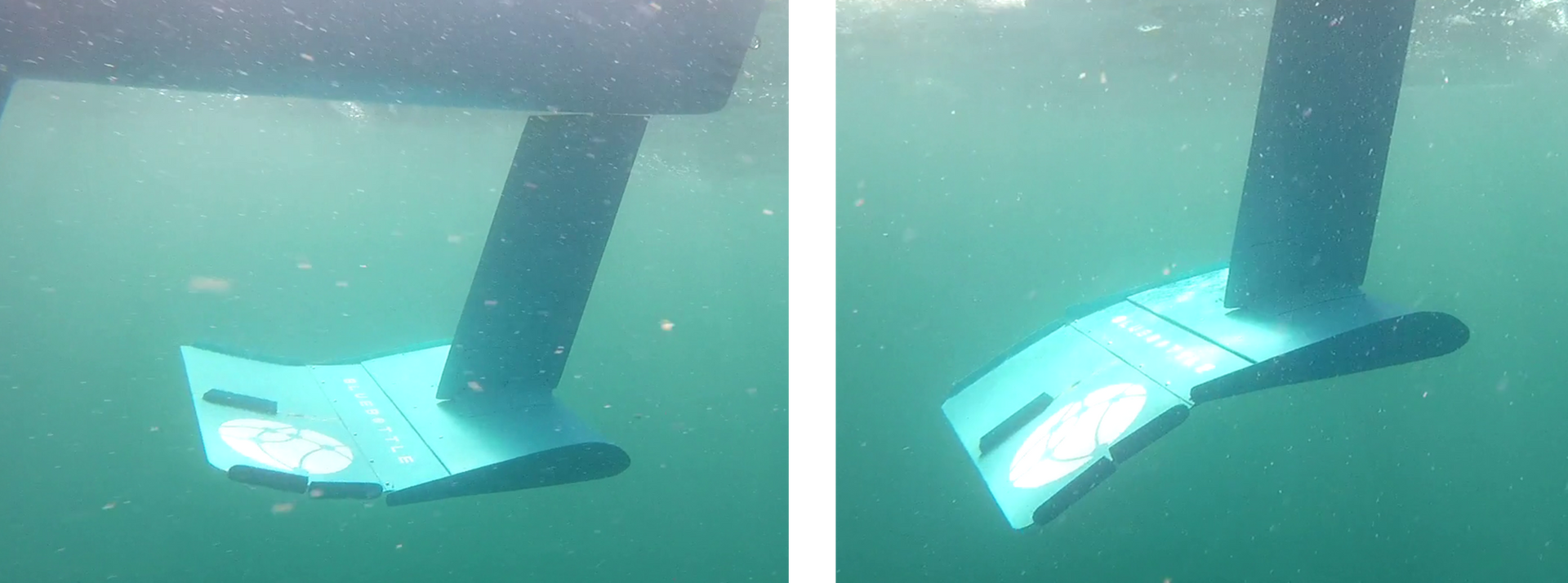

My research is focussed on the development of the Ocius flipper – a flexible foil that harnesses the heave of our boats to provide a passive means of wave induced propulsion.

3. When did you become interested in this field?

I first learned about wave power in high school with the Pelamis wave energy converter. It stuck with me. Interest in fluids and flow has been an interest for as long as I can remember.

4. What made you interested in it?

Growing up by the coast taught me a love for the ocean from an early age. Spending time surfing and sailing, I quickly developed an appreciation for the understanding of flow – not only in engineering design (fin, hull, and sails), but also in nature (waves, fish, weather). Having a dad in the composite boat building industry exposed me to developing technologies and got me hooked.

5. What do you hope to achieve through your PhD? What challenges are you hoping to solve?

The Ocius Bluebottle is an interesting blend of emerging and sustainable technology that makes a great platform for testing concepts such as the flipper. Through this project, I hope to provide a reliable flipper with measurable performance so that the Bluebottle can save power and stay at sea for longer periods of time. Some challenges include balancing flex and fatigue and tuning the flipper for varied sea conditions.

6. What are your long-term goals/ambitions?

Broadly, I hope to have a net-positive impact on the world. By working on/researching emerging technologies, I have an opportunity to influence the industries direction in a sustainable and ethical manner. As an engineer, I aspire to connect people with solutions.

7. What’s the best thing about being an ACM CRC PhD student?

Studying and working through the CRC is a unique opportunity to bridge industry and research. It is a great source of knowledge and a network with the Australian composites industry, and provides a practical research environment in which results are tangible and immediate.

8. What one piece of advice would you give to people thinking of undertaking a PhD in the composites manufacturing area?

There’s a lot of development potential in researching composites manufacturing, and applications are still emerging. It is a field that naturally connects a network of cutting edge (and interesting) technologies across many different industries. I would recommend post grad research to those with a hungry brain and I would recommend the composites manufacturing field to those who are interested in high performance materials and emerging technologies.

9. Tell us something about you that would surprise/impress people?

I have an exploratory itch that continues to push my comfort zone and has taken me sailing across the Pacific and Atlantic oceans in varied boats and roles.

Interested to know more?

Visit our Education and Training page to learn more on our HDR Program, and how it’s helping to achieve industry transformation.