9 questions with Chris Jenkins, ACM CRC PhD Student

We’re taking this opportunity to introduce each our PhDs to you – those who are playing a significant role within our program, and in the broader industry.

Here, we speak with Chris Jenkins, from one of ACM CRC’s university partners,

1. Under which ACM CRC Research Program does your PhD project sit?

My PhD project falls under Research Program 2 (Manufacturing Processes).

2. What is the focus of your PhD?

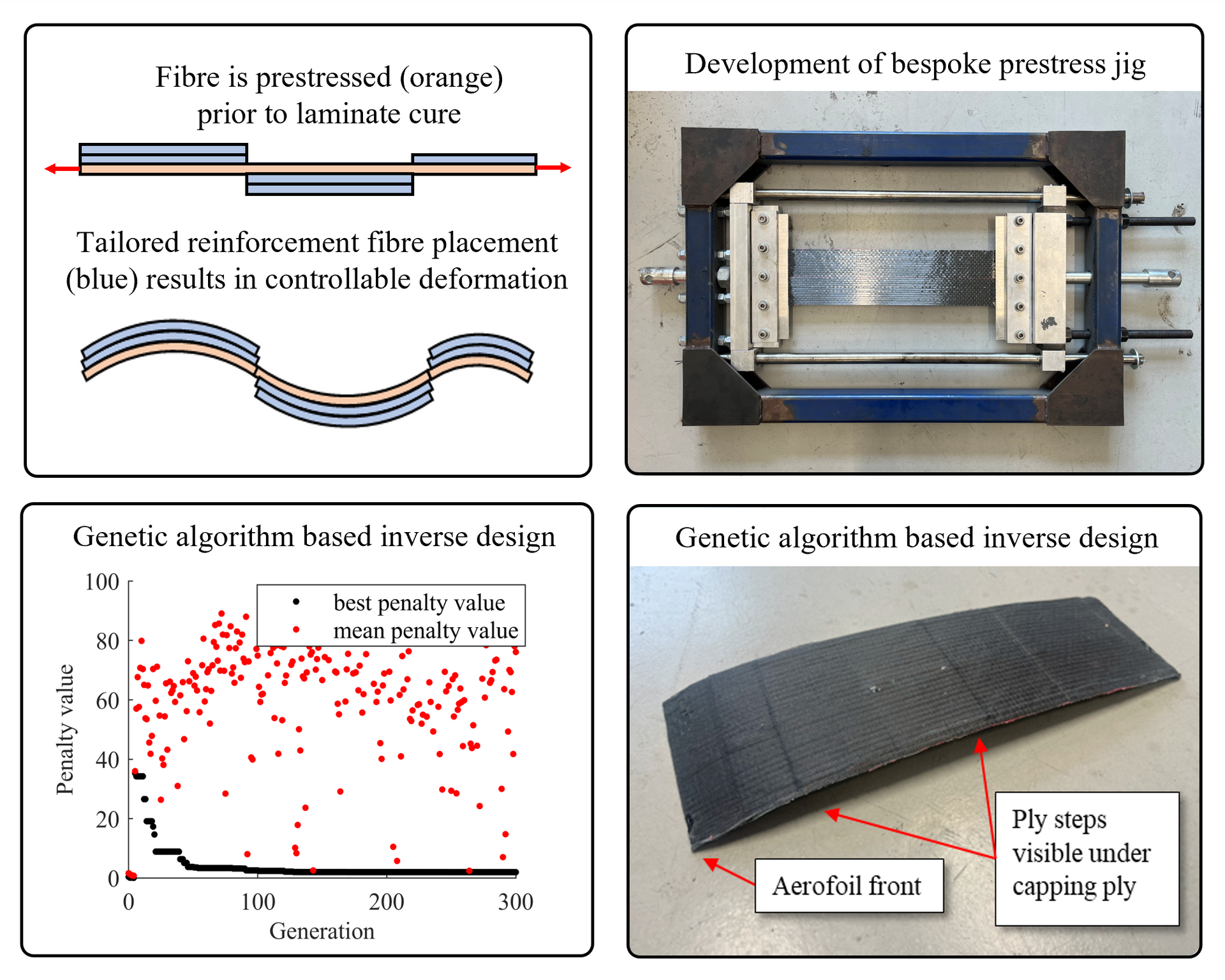

My PhD focuses on the mould-free fabrication of composite laminates. Mould tooling presents a time and capital barrier to rapid composite production. My research explores a technique that we’ve called ‘eccentric fibre prestress’, which aims to produce curved surfaces from an otherwise flat laminate by inducing deliberate process warpage.

3. When did you become interested in this field?

I formally started working with composites during my undergraduate degree, while designing and building Sunswift 7. Sunswift 7 is a 4-seater carbon fibre electric vehicle that we built to compete in the Bridgestone World Solar Challenge. I was curious well before then, however – I’ve always had a keen interest in mountain bikes, and composites are used extensively for light weighting there.

4. What made you interested in it?

As an outsider looking in, composite engineering is often viewed as a bit of “black magic”. I certainly held this view prior to working on the solar-electric car. When we began construction, it started to make more and more sense. This process of figuring out how to practically use composites was intriguing, and was the starting point for my PhD.

5. What do you hope to achieve through your PhD? What challenges are you hoping to solve?

By the end of my PhD, I’m hoping to have developed a design framework that will allow other engineers to use the eccentric prestress process that I’ve developed in their own applications. I’d like to outline which parts they can make with the materials that they have available, and describe the geometric and structural limitations too.

6. What are your long-term goals/ambitions?

I’d like to apply my research experience to the aerospace/automotive industry and develop the next generation of composite processes and components.

7. What’s the best thing about being an ACM CRC PhD student?

Being networked into the Australian composites industry right from university is a great opportunity and a highlight of the CRC.

8. What one piece of advice would you give to people thinking of undertaking a PhD in the composites manufacturing area?

Composites is not “black magic” and can be learnt. The freedom composites give over traditional engineering materials is huge, and I think that’s what makes research in this space exciting..

9. Tell us something about you that would surprise/impress people?

I’ve built my own mountain bike frame (bronze brazed chromoly steel). Hopefully there will be a composite in the near future!

Interested to know more?

Visit our Education and Training page to learn more on our HDR Program, and how it’s helping to achieve industry transformation.