8 Questions with Saral Mittal

Our PhDs are playing a significant role within our program, and in the broader industry.

Saral is a Mechanical Engineering PhD candidate with ACM CRC research partner, The University of New South Wales (UNSW Sydney).

Prior to this, he completed his Bachelor's degree with Honours in Mechanical Engineering at IIT Bombay, India. He also possesses significant industrial experience, having worked with Airbus as a Modeling & Simulation Engineer.

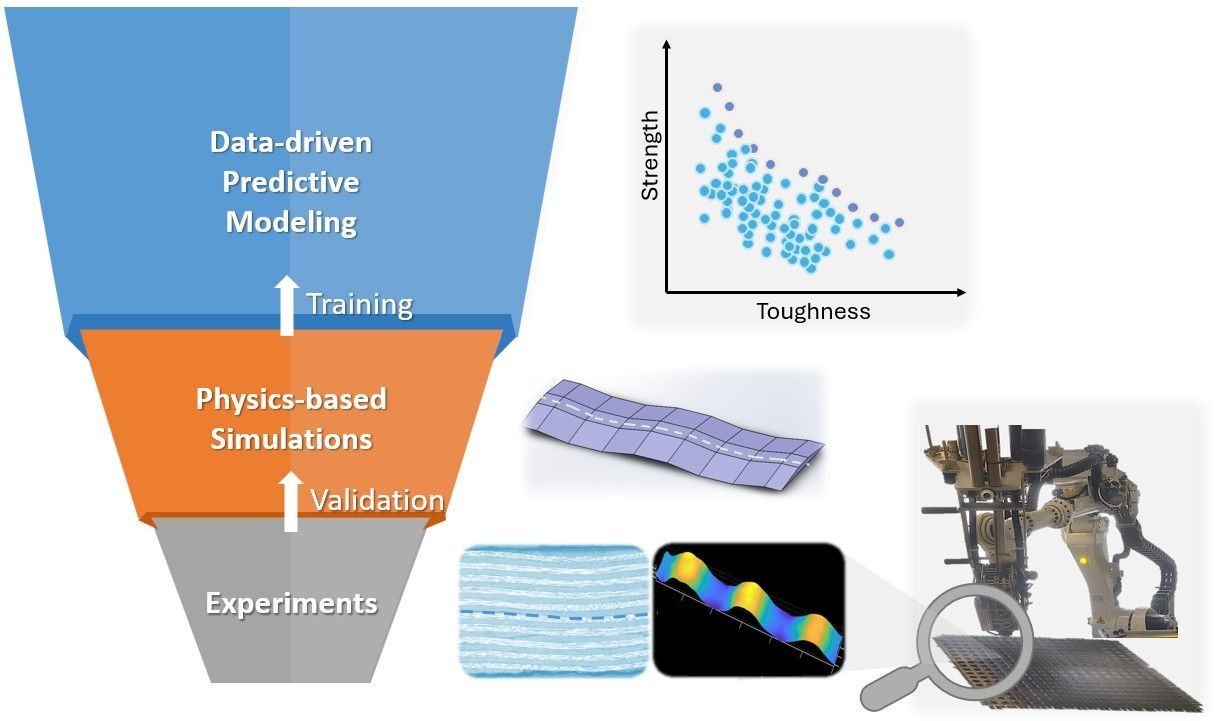

Saral's research focuses on developing an automated tow-wise layup design framework to achieve fit-for-purpose mechanical responses in continuous fibre composites. This involves an integration of cutting-edge additive manufacturing techniques, data-efficient neural network models, and nature-inspired hierarchical design principles. His work also includes the characterisation and numerical modelling of multi-scale structural features to accurately replicate the physical responses of advanced composite architectures. Saral is also working on a collaborative project aimed at uncovering hidden security flaws in automated composites manufacturing systems, designing novel security solutions to safeguard against cyber-sabotage.

Q1. Under which ACM CRC Research Program does your PhD project sit?

My PhD project falls under

Research Program 1 (Composite Materials),

Research Program 2 (Manufacturing Processes),

Research Program 3 (Simulation, performance prediction), and

Research Program 4 (Design, integration).

Q2. What is the focus of your PhD?

My PhD research focuses on developing an automated tow-wise layup design framework to achieve fit-for-purpose mechanical responses in continuous fibre composites. This work involves comprehensive mechanical and morphological investigations of advanced composite meso-architectures manufactured through Automated Fibre Placement, combined with a machine learning–led inverse design approach to identify the optimal design configurations tailored for desired physical behaviours.

Q3. When did you become interested in this field, and what made you interested?

My interest in this field began during my bachelor's thesis project at IIT Bombay, where I became deeply intrigued by the broader question of “how topology translates to mechanical behaviour”. What especially captured my attention was the emerging use of machine learning to navigate high-dimensional design spaces in search of optimised material architectures (a direction increasingly referred to as “Materiomics”). As I explored further, I noticed that while leading research groups and top tech companies were applying these methods to various material systems, there was a surprising lack of initiative in the context of continuous fibre composites, even though they form the backbone of many cutting-edge mechanical systems (such as aircraft structures). This gap presented both a challenge and an opportunity. The prospect of developing the first-of-its-kind automated design framework for continuous fibre composites strongly motivated me to pursue research in this direction.

Q4. What do you hope to achieve through your PhD? What challenges are you hoping to solve?

Traditionally, composite laminates have been designed from the perspective of stacked plies. However, the emergence of advanced manufacturing techniques such as Automated Fibre Placement (AFP) has fundamentally shifted how we approach both the fabrication and design of composites. These technologies have opened up entirely new design possibilities that can be manufactured at scale, but which no longer align with conventional ply-based design frameworks.

One such possibility is tow-wise layup, which has shown considerable promise in enhancing critical properties like impact tolerance. To fully harness such opportunities, existing design methodologies need to be fundamentally rethought.

Through my PhD, I aim to develop a new automated design framework that accounts for these novel layup strategies. This framework will computationally explore the vast design space enabled by tow-wise manufacturing and suggest optimal tow placement patterns tailored to specific mechanical requirements. The ultimate goal is to help engineers and designers realise the full potential of advanced composite architectures made possible by modern manufacturing technologies.

Q5. What are your long-term goals/ambitions?

I aspire to lead innovative research, that supports next-generation engineering applications, as a researcher within academia. My long-term goal is to identify and address fundamental gaps across engineering design and manufacturing. I am particularly passionate about developing novel material systems and structural solutions for extreme applications, as well as creating automated process workflows that streamline end-to-end product engineering. Whether through academic-industry partnerships or entrepreneurial spin-offs, I am committed to translating research into practical, scalable technologies.

Q6. What’s the best thing about being an ACM CRC PhD student?

The best part of being an ACM CRC PhD student is staying closely connected to real-world industry needs. This alignment helps ensure that your research remains not only technically sound but also practically relevant, avoiding the common trap of producing work that is academically correct but lacks industrial impact.

Being part of this ecosystem exposes you to how research translates into industry practice and how effective collaborations are built. It offers valuable insights into the pathways of innovation and allows you to learn directly from ongoing examples of research-to-industry integration.

Q7. What one piece of advice would you give to people thinking of undertaking a PhD in the composites manufacturing area?

I would advise choosing projects with some industrial connection to ensure your work stays relevant beyond academic papers. It’s important to tackle problems that matter, even if they lie outside your previous experience.

The skills, analytical abilities, and knowledge you bring are highly transferable and will serve you well throughout your research. It’s definitely possible to build a strong foundation in composites manufacturing during your PhD and leverage your existing strengths and experiences to develop novel applications and methodologies.

Q8. Tell us something about you that would surprise/impress people.

I’m really into performing arts - especially dancing and filmmaking. Even though I’m definitely not the most talented at either. Luckily, I found my second calling in research where I can still keep the creative spark alive.

Interested to know more?

Visit our Education and Training page to learn more on our HDR Program, and how it’s helping to achieve industry transformation.