10 Questions with Dr Vladislav Yakubov

Dr Vladislav (‘Vlad’) Yakubov is an additive manufacturing postdoctoral research associate at ACM CRC research partner, The University of Sydney.

He received a PhD in mechanical engineering in 2022, and brings a wealth of expertise to ACM CRC Project APN006: Circular Design 4.0 – AI-based Quality Control, Manufacturing.

His specific areas of interest include additive manufacturing techniques and material characterisation.

1. Within which ACM CRC Research Program/s are you working?

I am working within Programs 2) Manufacturing Processes, 3) Simulation, Performance Prediction, and 4) Design, Integration.

2. What was the focus of your PhD?

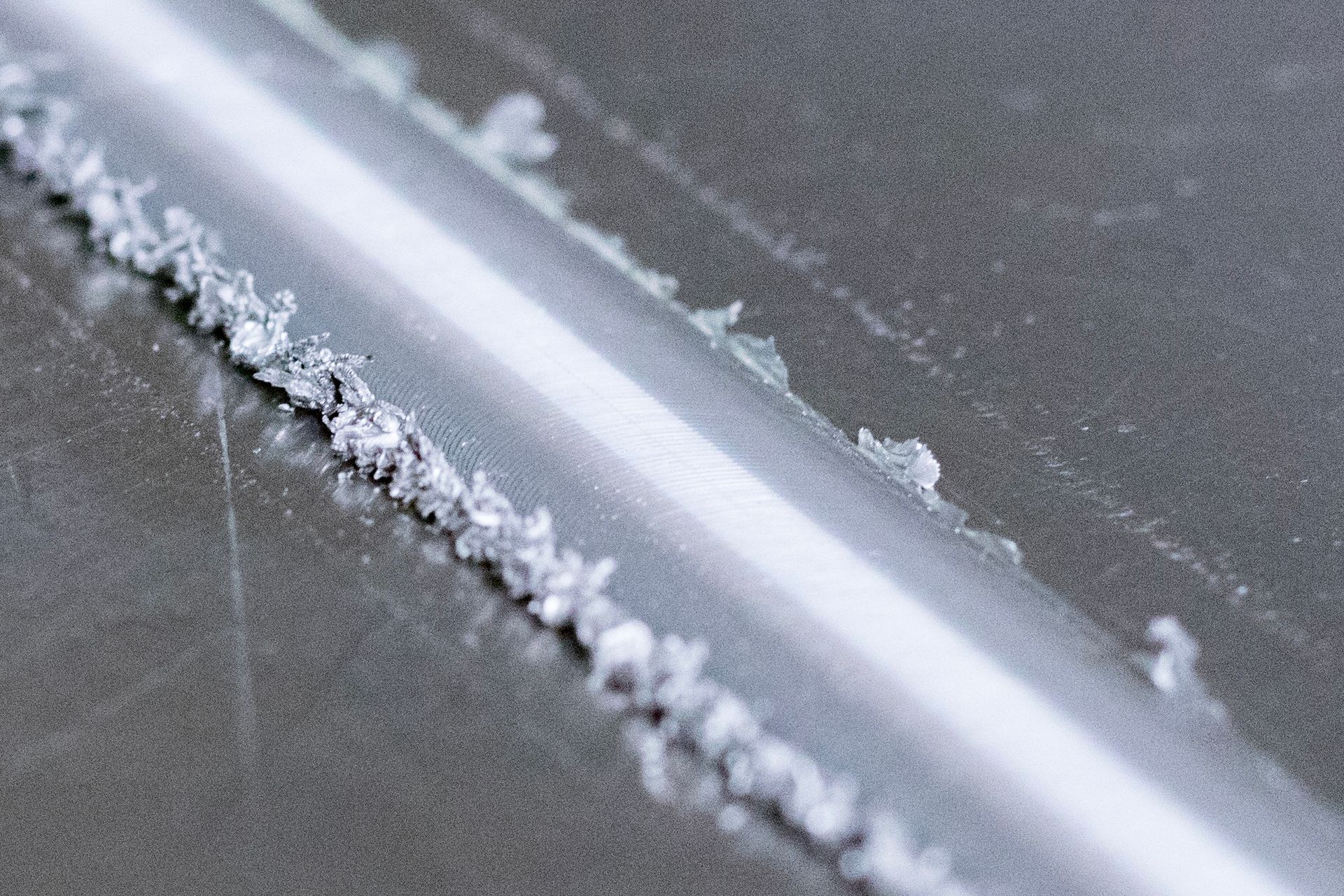

The focus of my PhD was on laser powder bed fusion (LPBF) additive manufacturing of Al-Ce-Si alloys.

My research was aimed to address some of the key challenges associated with processing aluminium-based alloys in additive manufacturing, specifically in terms of controlling microstructure and reducing defects.

Aluminium-cerium alloys have unique benefits for high-temperature applications and excellent printability in additive manufacturing, making them ideal for industrial applications that require both lightweight and high-performance materials.

Throughout my PhD, I worked on tailoring the process, characterising microstructure, and evaluating the mechanical properties of the manufactured parts, with the goal of improving the performance of these alloys for use in aerospace, automotive, and other demanding industries.

This work also involved significant experimentation with alloy design and thermal management strategies since this significantly impacted the manufacturing outcome.

3. When did you become interested in this field?

I became interested in additive manufacturing and materials engineering during undergraduate materials research in Asia in 2016, 2017, and 2018. This was funded by my undergraduate supervisor at the University of South Florida as part of a National Science Foundation grant.

4. What made you interested in it?

My interest in additive manufacturing was sparked by the realisation of how transformative this technology could be in enabling rapid prototyping and design freedom. During my undergraduate research, I witnessed first-hand how additive manufacturing could revolutionise manufacturing, allowing for the creation of complex geometries that were previously impossible or highly inefficient to produce.

This potential for innovation, combined with the interdisciplinary nature of the field, drew me into the research. Additionally, the prospect of contributing to advancements that could improve sustainability of heavy industry was a key motivator.

5. What can your PhD bring to the CRC? What challenges are you hoping to solve?

In my later work, I gained expertise in understanding other metal additive manufacturing processes such as additive friction stir deposition (AFSD). This knowledge can be directly applied to the CRC's goals of enhancing manufacturing processes and developing high-performance materials.

I hope to tackle challenges related to the non-uniform mechanical properties development, optimise additive manufacturing processes for recycled and composite materials, and contribute to the development of new alloys and composites that can meet the demands of advanced applications.

6. What are your long-term goals/ambitions?

My long-term goal is to become a leader in the field of additive manufacturing and materials engineering, driving innovation and contributing to the development of sustainable and high-performance materials.

I aim to work at the intersection of industry and academia, where I can translate cutting-edge research into practical applications. Ultimately, I want to contribute to advancements in aerospace, defence, and other high-tech industries, where materials performance is critical.

I am also passionate about mentoring the next generation of researchers and engineers, and I hope to inspire others to explore the possibilities within this dynamic field.

7. What’s the best thing about being an ACM CRC Postdoc Researcher?

The best part of being an ACM CRC Postdoc Researcher is the opportunity to collaborate with leading experts in the field of additive manufacturing and composites. The multidisciplinary environment fosters innovation and allows me to work on cutting-edge projects that have the potential to make a real impact. Additionally, the resources and support provided by the CRC enable me to push the boundaries of research, experiment with new ideas, and continuously learn and grow as a researcher.

8. What one piece of advice would you give to researchers thinking of working in the composites manufacturing area?

My advice would be to stay curious and open to learning from different disciplines. Composites manufacturing is an interdisciplinary field that combines materials science, engineering, and advanced manufacturing techniques.

Having a broad understanding of these areas will help you tackle complex challenges and innovate in your research. Don’t be afraid to push boundaries, experiment with new approaches, and collaborate with others who have complementary expertise.

9. Tell us something about you that would surprise/impress people?

One surprising fact about me is that I’ve had the opportunity to conduct research in Asia during my undergraduate years, leading to several publications. I was involved in projects that spanned advanced materials research and cutting-edge manufacturing, which not only broadened my technical knowledge but also provided me with a unique cultural perspective on international collaboration in science and engineering.

The experience was admittedly quite challenging, and the work was fast-paced, but it helped shape my approach to challenges both in the lab and in life, by teaching me the importance of resilience, adaptability and teamwork.

10. Anything to add?

I’m passionate about the potential of additive manufacturing to contribute to a more sustainable future by reducing material waste and energy consumption in manufacturing processes. I’m excited to continue working on innovative projects that push the boundaries of what’s possible in this field, and I’m always open to new collaborations and opportunities to make a positive impact in the world.

Interested to know more?

Visit our Education and Training page to learn more on our HDR Program, and how it’s helping to achieve industry transformation.