10 Questions with Abila Anayet

Our PhDs are playing a significant role within our program, and in the broader industry.

Abila is a PhD Student with ACM CRC Partner, The University of Sydney (USYD), prior to which she completed her Bachelor’s degree in Civil Engineering from Universiti Teknologi Malaysia (UTM) with First Class Honors.

Abila has a strong academic and research background in sustainable construction materials and environmental engineering.

She is currently pursuing her PhD in Civil Engineering, focusing on the application of Artificial Intelligence (AI) for quality control in structural steel fabrication. Her work aims to optimise Non-Destructive Testing (NDT) methods to improve fabrication efficiency, minimise defects, and ensure compliance with Australian Standards.

Q1. Under which ACM CRC Research Program does your PhD project sit?

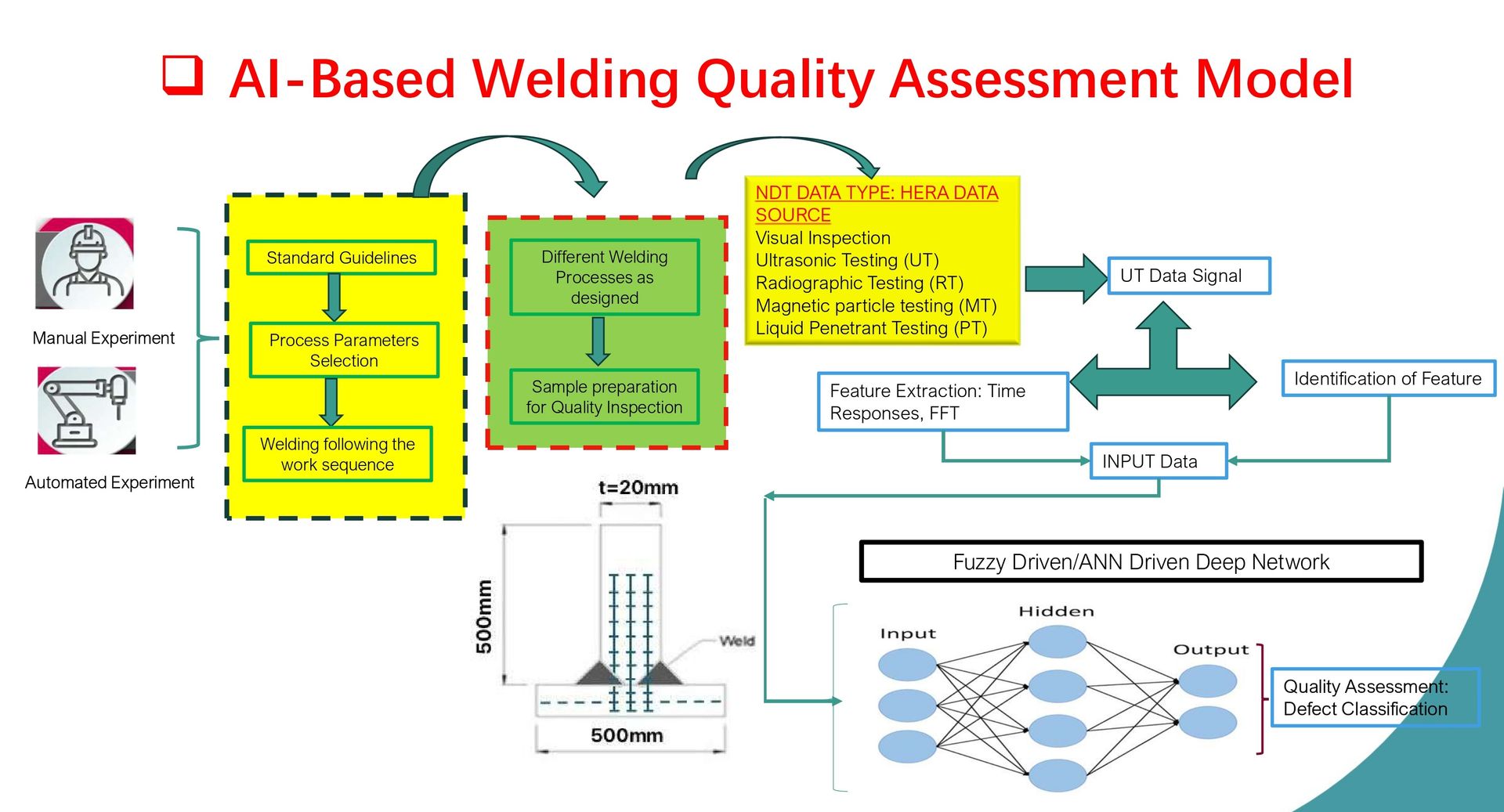

My PhD falls under Research Program 2: Manufacturing Processes, which focuses on revolutionising fabrication through intelligent systems, sensor technologies, and AI-enabled quality control. My research contributes by developing a data-driven weld inspection framework for structural steel, using machine learning, neutron imaging, and Non-Destructive Testing (NDT) to help deliver smarter, standards-aligned outcomes in real-world fabrication.

Q2. What is the focus of your PhD?

I’m developing an AI-enhanced quality control system for welded structural steel, especially for complex T-joint configurations. My approach combines Finite Element Analysis (FEA), machine learning, Non-Destructive Testing, and neutron imaging (like tomography and diffraction) to detect internal weld defects, evaluate fusion quality, and map residual stress. The bigger goal is to create a smart, reliable inspection tool that improves fabrication quality, reduces rework, and supports updates to international welding standards. This system also contributes to a broader structural health monitoring approach for diagnosis and prognosis, enabling more proactive and data-driven decision-making in structural engineering.

Q3. When did you become interested in this field?

It started during my undergraduate studies, when I was working on sustainable construction materials. That project got me thinking about how materials behave in real structures and how failure often begins in ways we don’t immediately see. Later, when I came across real-world challenges in welding and fabrication, I realised how important quality control is in keeping structures safe. That’s when I really knew this was a space I wanted to explore further.

Q4. What made you interested in it?

I’ve always been fascinated by problems that aren’t easy to spot, especially in engineering. The idea that a tiny flaw inside a weld could affect the safety of a whole structure really stuck with me. When I saw how technologies like AI and neutron imaging could help uncover those hidden risks and improve how we build, I felt genuinely excited. It felt like the kind of work where I could combine innovation, purpose, and impact—and actually make a difference.

Q5. What do you hope to achieve through your PhD? What challenges are you hoping to solve?

Through my PhD, I hope to create a more reliable and intelligent approach to quality control in structural steel fabrication – one that doesn’t just detect flaws but understands them in context. A major challenge I’m addressing is the difficulty of identifying internal weld defects in complex geometries like T-joints, where traditional inspection methods often fall short. I want to develop a system that uses AI to improve how we assess weld quality, reduce rework, and make fabrication more efficient, consistent, and standards-compliant. In the long term, this framework also supports a structural health monitoring approach, offering valuable insights for both diagnosis and prognosis of structural performance over time.

Q6. What are your long-term goals/ambitions?

In the long term, I see myself staying in the research sector, where I can keep exploring how technologies like AI and advanced testing methods can improve structural quality and safety. I’m passionate about building systems that have real-world impact, and I want to contribute to shaping smarter, more efficient engineering practices. I also hope to share what I’ve learned with the next generation of engineers and researchers through mentoring, teaching, and collaborating on future projects.

Q7. What’s the best thing about being an ACM CRC PhD student?

One of the best parts of being an ACM CRC PhD student is the chance to do research that’s deeply connected to industry. I get to collaborate with people from across universities, fabricators, and research organisations like HERA and ANSTO, which makes the work feel purposeful and grounded. It’s rewarding to know that my project could help address real challenges in fabrication and inspection, and potentially shape future standards.

Q8. What one piece of advice would you give to people thinking of undertaking a PhD in the composites manufacturing area?

Pick a problem you genuinely care about and not just something that sounds impressive on paper. A PhD is a long journey, and what will keep you going is curiosity and the belief that your work matters. Also, don’t be afraid to ask questions or take the time to build the right support network. Research can feel isolating at times, but being part of a collaborative environment like ACM CRC makes a huge difference.

Q9. Tell us something about you that would surprise/impress people.

Most people are surprised to learn that outside of engineering, I genuinely love teaching and getting involved in extracurricular activities alongside my research. I believe we shouldn’t limit ourselves, and that there’s always something valuable to learn beyond our own field. I’ve taken part in over 230 academic, cultural, and leadership activities, and these experiences have shaped the way I think, lead, and collaborate. They’ve also taught me that innovation doesn’t always come from labs or code. It often begins with conversations, fresh perspectives, and the people around us.

Q10. Anything to add?

I’ve never believed in fitting into boxes, especially in research. There isn’t just one path to making a difference or one way a researcher is supposed to look. I’ve found that some of the most meaningful work happens when you trust your instincts and follow ideas that don’t always fit the mould. Being part of ACM CRC has shown me that there’s space for new ways of thinking, for collaboration, and for doing things differently. I hope my journey encourages others to trust their own path and know there’s no single way to make a difference.

Interested to know more?

Visit our Education and Training page to learn more on our HDR Program, and how it’s helping to achieve industry transformation.